Capabilities

Capabilities

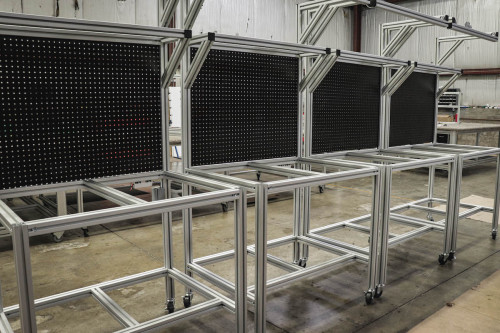

T-slot aluminum extrusions & related assembly hardware sold directly from Framing Tech to the end user. Material fulfillment as raw-lengths, kit-form, sub/fully assembled, or installed at your location. In-house engineering support using the latest software from SolidWorks, bringing your concept from idea to reality. We partner with automation, robotic & equipment OEMs to refine our processes by developing standards & best practices to provide highly aesthetic solutions.

- Immediate availability of information. Call 585.464.8470 or email: Sales@FramingTech.com.

- Quoting & material fulfillment in 24 hours or less for most projects.

- We are a 21st century manufacturer offering solutions to age-old equipment challenges using state-of-the-art equipment & highly experienced personnel.

Material Sales:

- Raw or bulk material sales of aluminum extrusions and their related hardware and accessories.

- Kit-form: Fully machined, labeled with an associated BOM and ready-to-assemble.

- Sub assembled.

- Fully assembled products - Shipped complete.

- On-site installation or consultation available by Framing Tech personnel.

CAD Design:

- Solidworks - multiple seats.

-

- 3D modeling, rendering, technical documentation, structural analysis.

- Translate from a hand-sketch or any CAD format content.

- Concept drawings or models may be sent for client review & approval prior to cutting metal.

- Assembly documentation sent with kits will have Item Balloons with corresponding strut labels.

- CAD (.stp) files are available for download directly from our website or 3D Content Central.

CNC: Machine Code generated by SolidCAM, MasterCam & HSMXpress:

- Vertical machining centers:

-

- FOM Axel 5 - 5 Axis Profile Machining Center - 22kW, 24k RPM, 7.5m Stroke (operational Spring '23)

- Fanuc Robodrill

- Chiron FZ-18L - 2m (78") stroke

- Flex CNC 2' x 10' 3-Axis Vertical Machining Center with a 4th rotary-axis (stand-alone)

Saw-Cutting of our Aluminum Profiles:

- Semi-Automatic 600mm (24") & 500mm (20")

-

- Air over oil hydraulic (controlled) feed rate, auto lubrication, L/R miter capable.

- DRO's are Tigerstop with 12' timing-belt servo-actuators, accuracy +/- .005" <8'.

- Manual chop saws, bandsaws (vertical & horizontal), drill presses, portable saws (used on installs).

AXYZ - 8' x 12' Panel & Plate, CNC Machining Center with automatic tool changer & separate blade

Vertical Knee Mills, with dedicated vertical machining fixtures & manual turret lathe

- Multiple manual knee mills (Bridgeport & Tree) with dedicated fixturing for repetitive operations

- Sugino/Hypneumat semi-automatic milling/drilling fixtures.

- Manual Turret Lathe

Durma - 66 Ton x 8' Hydraulic Press Brake with CNC Back-Gauge

Chicago Dreis & Krump - Box & Pan (finger) Brake - 12ga. 72”

WARDJet - E-1530, 5' x 10' Waterjet - cuts virtually any material

Holzher Horizontal Table Saw with bearing-sled

Niagara Shear - 3/16" Plate Steel & Wire Mesh (typ)

Multiple Miller/Lincoln Welders for TIG/MIG, Aluminum Spool-Gun, Stick, etc.

- Aluminum, Stainless, Steel, Plastic

- Miller Plasma Cutter

Flex-Arm: GHM-45 Hydraulic Tapping - Capacity: 1 ½” Steel

Volumec JT3150 Electric Tapping-Arm (M3-M16 Capacity) Aluminum

Prototyping:

- We can help concept your ideas & provide prototypes virtually or in working examples.

Installation of your project.

- From initial Consultation to an OSHA certified assembly team, we can help you put it all together.

Send us your Scope of Work to see how we can help!