March 30, 2019

Guest blog by Frank Weaver

There’s a very good reason why FramingTech’s “go-to” material for its machine guard and workplace enclosures, aquarium stands, shelving, and other extruded T-slot solutions is aluminum. This abundant metal’s superior strength-to-weight ratio, workability, elasticity, corrosion-resistance, and low cost (relative to steel) makes it the ideal choice—structurally, aesthetically, and performance-wise—for a wide variety of demanding applications.

For that same reason it is safe to say that modern aviation—civilian and military—simply would not exist without aluminum. This fact cannot be more clearly illustrated than with the U.S. Air Force’s legendary Boeing B-52 Stratofortress strategic bomber.

A B-52H on display with armaments at Barksdale AFB, Shrevport, LA

While the above photo may be impressive, I can state unequivocally that the aircraft is even more impressive in person.

I had occasion recently to visit my elder son at Barksdale Air Force Base in Shreveport, Louisiana, where he is currently stationed and serves as a weapons navigation systems officer aboard their fleet of B-52s.

This long-range, large-payload, multi-role bomber is the USAF’s principal strategic nuclear and conventional weapons platform, and it supports the US Navy in anti-surface and submarine warfare missions. I had come to see my son graduate from Barksdale’s Formal Training Unit (“FTU”); and after the ceremony I was given an up-close-and-personal tour of one of the B-52s on which he flies.

“Teddy’s Buff Riders” B-52 FTU Patch

Let me tell you, this plane is one huge behemoth to behold with one’s own eyes. Photographs simply do not do it justice.

And yes, it does look sort of ungainly. (Which is why no one ever refers to the aircraft by its official “Stratofortress” moniker; instead, the people who fly the B-52 refer to it affectionately as BUFF: Big Ugly Fat Fella.) While these planes are quite old, they are also incredibly reliable workhorses.

Although the B-52 has been in active service with the USAF since 1955, its superior performance at high subsonic speeds and relatively low operating costs have allowed it to remain in service with the Air Force Global Strike Command (AFGSC) to this day. In some key respects, it outperforms more advanced aircraft. Indeed, the USAF intends to keep their model B-52H fleet in service until the year 2045. That is close to 90& years after the B-52 first entered service—an unprecedented length of service for any civilian or military aircraft design in history.

The B-52H is almost 160& feet long and 40& feet high on the runway, with a wingspan of 185& feet and wing area of 4,000& square feet. That’s a lot of aluminum! In fact, empty of fuel and payload, the B-52H weighs 185,000& pounds; and aluminum makes up some 90% of that weight, mostly in the airframe and “skin” of the aircraft. (The landing gear assemblies, 8& powerful turbofan jet engines, and computers and electronics, along with other interior controls and “amenities,” make up the remainder of that total weight.) And yet this “aluminum fortress” is capable of taking off fully fueled (48,000& gallons) with payload (70,000& pounds) that more than doubles its weight to 488,000& pounds.

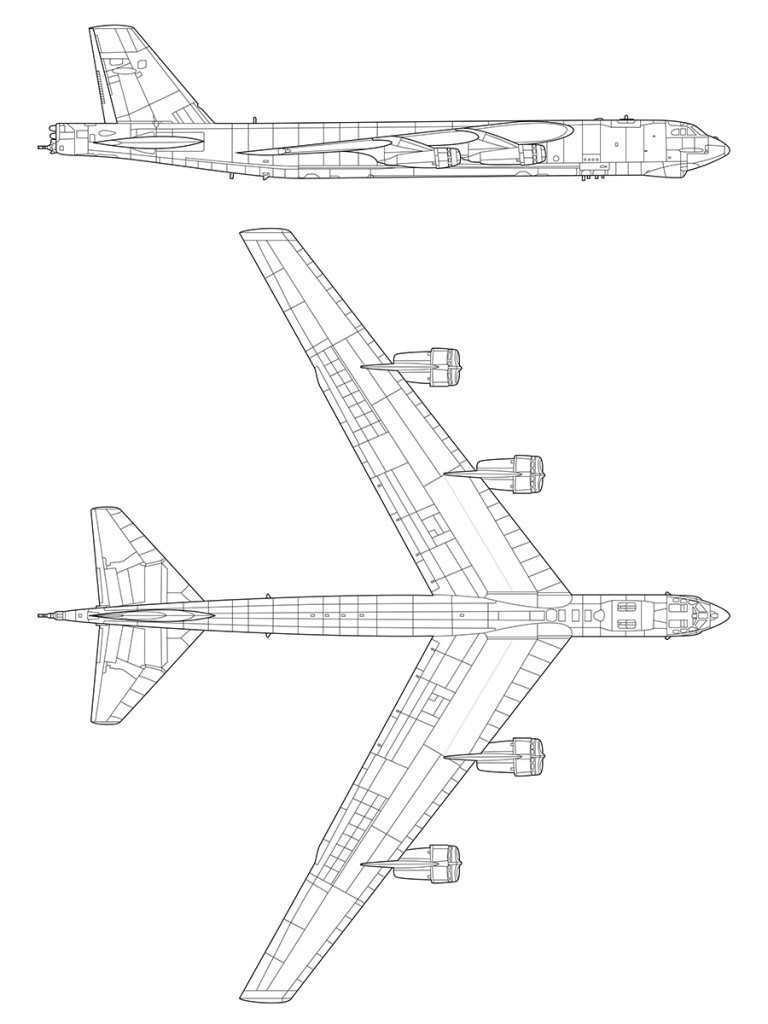

Side- and top-view projections of the B-52H

Once airborne, it can fly as high as 50,000& feet above sea level, well beyond the lower edge of the stratosphere (hence the name “Stratofortress”); and it can attain a top speed of 560& knots, or 650& mph. In 1962, a B-52H set a long-distance flight record, without refueling, of 12,532& miles—which is almost exactly halfway around the world. With capabilities like these, no wonder the Air Force keeps their B-52s in service!

I did not get to see much of the interior of the B-52, as it is “classified.” However, the short video below shows various aspects of the aircraft’s exterior—the aforementioned aluminum skin. They can call it “BUFF” if they want; but I find it beautiful.

When it comes to aluminum, my big takeaway from the tour my son gave me is this: if it’s good enough for the U.S. Air Force, it’s good enough for FramingTech!